In the optical market, 3D printing is a technology in full swing. Nevertheless, it can hardly become widespread because of its high price and a lower quality than the traditional offer. In view of the above, Aoyama and Unistudio decided to create a new brand offering unique products, making 3D-printed glasses more accessible.

As a first step, a workshop was organised in order to identify the DNA of the brand, individual models to be part of the first collection as well as the brand-centred communication. We have decided to use 3D printing to manufacture the range that would allow us to create a multitude of shapes, sizes, and colours.

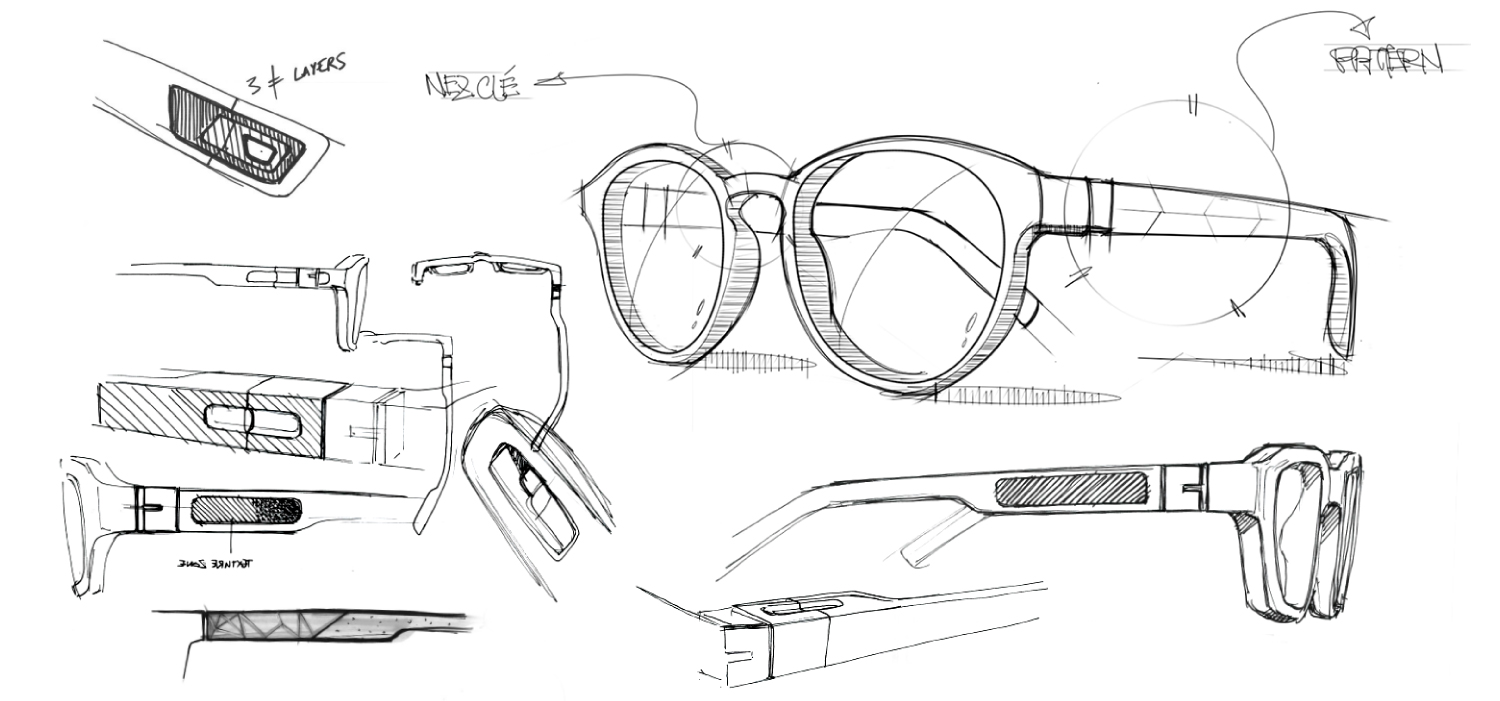

The next step was to draw on paper the results of all our brainstorming ideas. This helped to find the exact shapes to give to the glasses.

Different styles of glasses were suggested to the Aoyama team, which we then fine-tuned together. The 14 selected models were subsequently prototyped in our workshop.

Based on the observations of the printed models, we made the final 2D touches to the frames. Then, the team drew sketches in order to work out the details and explore the items on the arms.

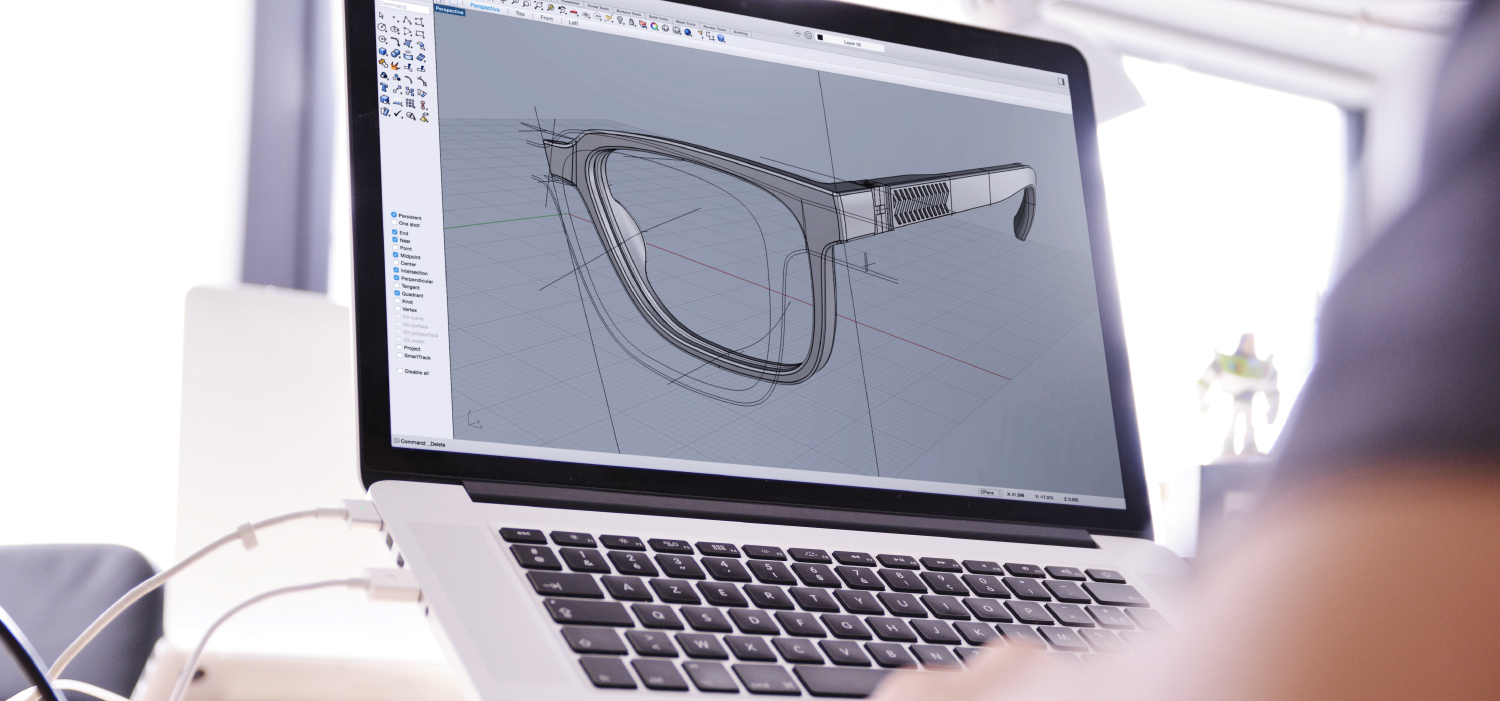

Requirements imposed by the 3D printing process as a manufacturing tool resulted in great precision of the 3D modelling for the preparation and assembly of each model. It was essential, in technical terms, to create a well-developed and ready-for-production product.

3D printing was also an important tool in the designing stage since many prototypes were printed in order to adjust the curves, the shapes, and the nature of each model. Indeed, we believe that at that stage of the project, it is relevant to compare and discuss the prototypes and models.

The final step was to choose the desired colours for the glasses. Designers had to also take into account the current trends for both men and women in order to offer a pair of recognisable glasses, with a unique character.

As part of the client support and assistance approach, we additionally deliver photo-realistic rendered images, shooting images, as well as the packaging for communication purposes.

To learn more about WeDDD, check out the following press articles: Press articles